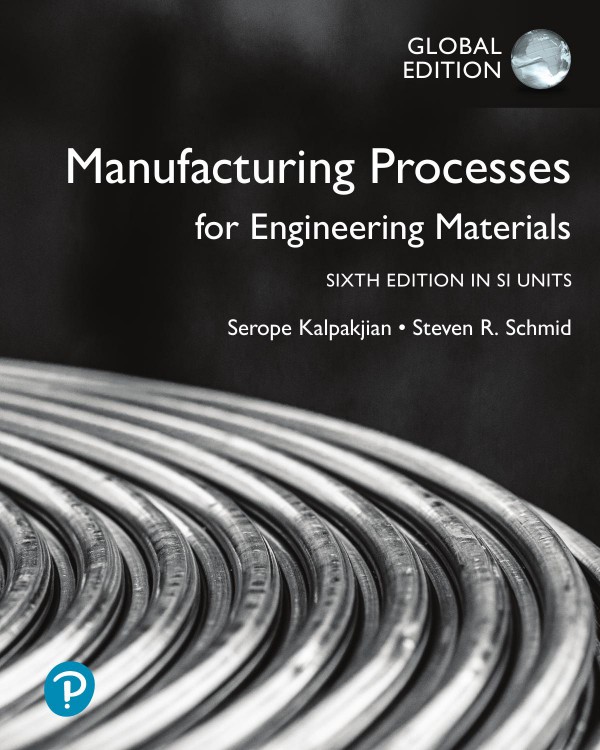

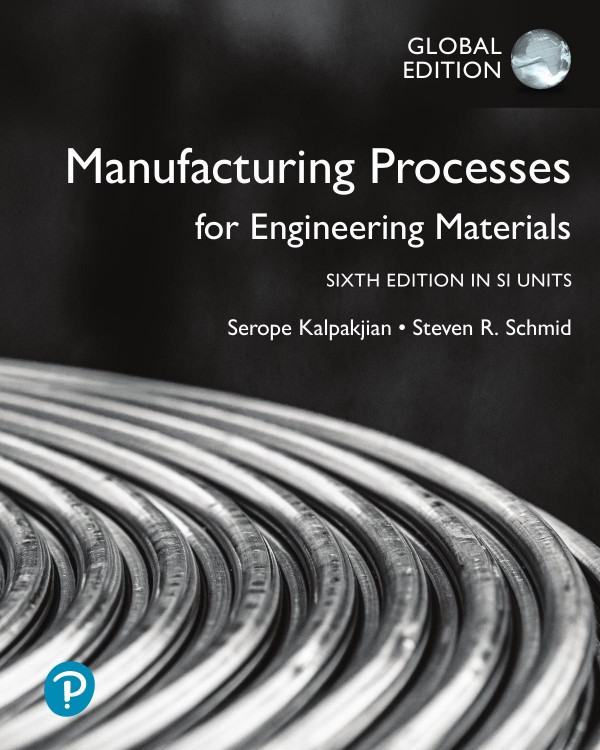

Manufacturing Processes for Engineering Materials in SI Units 6th edition by Serope Kalpakjian, Steven Schmid 9780134425115 0134425111

Original price was: $50.00.$25.00Current price is: $25.00.

Authors:Serope Kalpakjian; Steven Schmid , Series:Mechanical engineering [83] , Tags:Technical & Manufacturing Industries & Trades; Mechanical; Mechtronics , Author sort:Kalpakjian, Serope & Schmid, Steven , Ids:9781292254388 , Languages:Languages:eng , Published:Published:Jun 2022 , Publisher:Pearson , Comments:Comments:Thistitle is a Pearson Global Edition. The editorial team at Pearson has workedclosely with educators around the world to include content which is especiallyrelevant to an international and diverse audience. Forundergraduate courses in Mechanical, Industrial, Metallurgical, and MaterialsEngineering Programs or for graduate courses in Manufacturing Science andEngineering. ManufacturingProcesses for Engineering Materials addressesadvances in all aspects of manufacturing, clearly presenting comprehensive,up-to-date, and balanced coverage of the fundamentals of materials andprocesses. With the 6th Edition in SI Units, students learn toproperly assess the capabilities, limitations, and potential of manufacturingprocesses and their competitive aspects. The authors present information thatmotivates and challenges students to understand and develop an appreciation ofthe vital importance of manufacturing in the modern global economy. Thenumerous examples and case studies throughout the book help students develop aperspective on the real-world applications of the topics described in the book.As in previous editions, this text maintains the same number of chapters whilecontinuing to emphasize the interdisciplinary nature of all manufacturingactivities, including the complex interactions among materials, design, andmanufacturing processes.